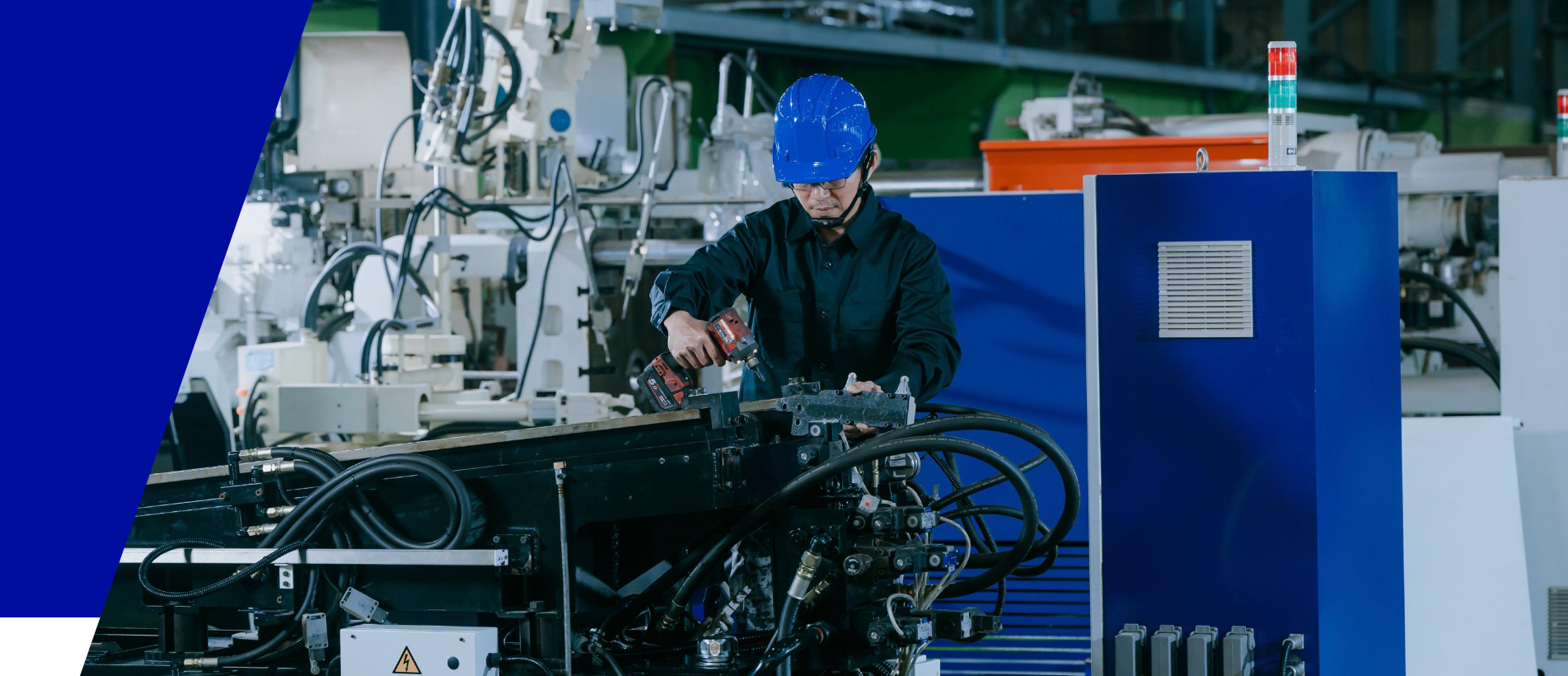

Precision Meets

Agility

A trusted development partner for military-grade precision machinery, specializing in highly customized technical integration. From concept to completion, we deliver agile, efficient, and precise expertise to meet diverse cross-industry demands.

Service Process

Advantages

Three key advantages of our specialized manufacturing integration service

01Needs-driven, Design LedNeeds Assessment, Design First

From needs discovery to design implementation, we solve your technical challenges end-to-end.

Design consultation is the first step to realizing your ideas. We begin by deeply understanding your needs and transforming them into actionable design proposals. Backed by industry experience and manufacturing capabilities, we serve as a technical bridge to real-world solutions.

Needs Analysis

Through in-depth exploration and multi-level communication, we understand your goals and constraints. We further integrate process feasibility and material properties to ensure the proposed design is practical and achievable.

Design Proposal

From structural design to material and component selection, we use 3D proposals that combine material properties and process feasibility. With rigorous analysis and client feedback, we turn your concepts into tangible, reliable design solutions.

Design Delivery

After design confirmation, we deliver technical drawings compliant with industry standards. You may choose to proceed with in-house production or collaborate with external partners.

02One-stop SolutionFrom Idea to Reality

From concept to completion, complete manufacturing and technical support

Our solutions cover mechanical design, diverse metal machining, and automation control—providing services that are both efficient and flexible. Every technique reflects years of accumulated expertise, ensuring seamless transitions from idea to product.

Mechanical Design

We integrate years of project experience to design mechanical structures that are stable, high-performing, and smooth in operation.

With 3D printing and machining capabilities, we accelerate prototype development and design validation—the first step to making your concept a reality.

Diverse Metal Machining

With a diverse range of machining equipment and technologies, we offer comprehensive services including turning, milling, drilling, tapping, and more.

Our equipment includes 5-face machining centers, platform lathes, and floor-type boring mills. We handle complex structures, long and large workpieces (up to 3m x 9m) with precision and flexibility.

Supported materials include aerospace-grade aluminum (6061, 6063, 7075), gray iron (FC), and ductile iron (FCD).

Automation Control

Combining PLC programming, system control, sensor integration, and HMI design, we support the realization of required automation and mechanical motion.

We produce military-grade cables, control boxes, and controllers compliant with MIL-STD 810G and EMI standards.

03Support SystemTotal Commitment, Worry-Free Trust

From production management to after-sales, a complete support system

A comprehensive support system is our commitment. From project kickoff to warranty service, every step is tightly managed to provide dependable technical assistance and product assurance—maximizing the value of long-term collaboration.

Long-Term Partnership

From small part prototyping to large-scale project execution, from in-house capabilities to supplier coordination, we provide strategic technical support throughout all stages of your development—helping you break through bottlenecks.

Production Management

From material procurement and inventory to production monitoring, we ensure reliable delivery and fulfillment across the entire production process.

Maintenance & Warranty

We provide responsive after-sales service to ensure product stability and reliability in your specific application environments.