Automation Machine and Equipment

Exclusively designed for SIMHOPE die casting machines, we have prepared all the automatic equipment you need, to help you achieve more with less.

:

:

:

Automation Machine and Equipment

One machine is good, why not do more with peripheral automatic equipment. We exclusively design extractor, sprayer, conveyer and trim press machines for SIMHOPE die casting machines. Achieve more with less with SIMHOPE’s solution.

Aesthetics

An art piece on your production line

A unique color palette, pure yet passionate and creative. When we keep pushing ourselves to achieve better, we make manufacturing become a process of creating beauty.

Everything we build not only offers safety and all the needed functionality for these type of machines, but it also showcases the beauty found in intricate and detailed manufacturing.

Safe & Reliable

While you take care of production; we take care of the rest

While you focus on production, you focus on production. Safety and high reliable machine structure are two elements that SIMOPE would never compromise.

The full cover design not only looks modern but also provides more safety.

The electronic & hydraulic double-check system will remove any potential danger. Moreover, hydraulic pressure will automatically release when an emergency stop happens or in the case of an unforeseen “power off” to avoid the potential danger of remaining pressure.

The electronic & hydraulic double-check system will remove any potential danger. Moreover, hydraulic pressure will automatically release when an emergency stop happens or in the case of an unforeseen “power off” to avoid the potential danger of remaining pressure.

Do more with less

Achieve more with less with SIMHOPE’s solution

One machine is good, why not do more with peripheral equipment

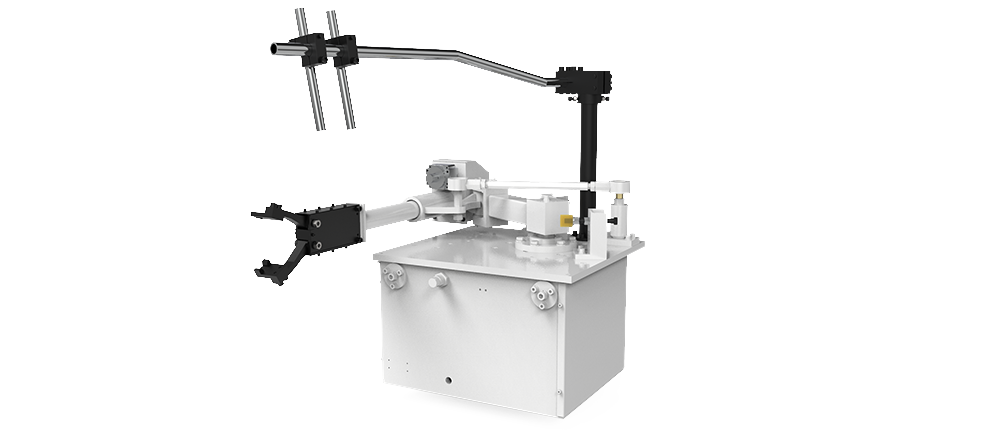

Extractor: release yourself from manual work without worrying about product damage and while maintaining production efficiency.

Sprayer: allowing mold-release agent to be sprayed evenly, thus ensuring that your product remains perfect at the time of demolding.

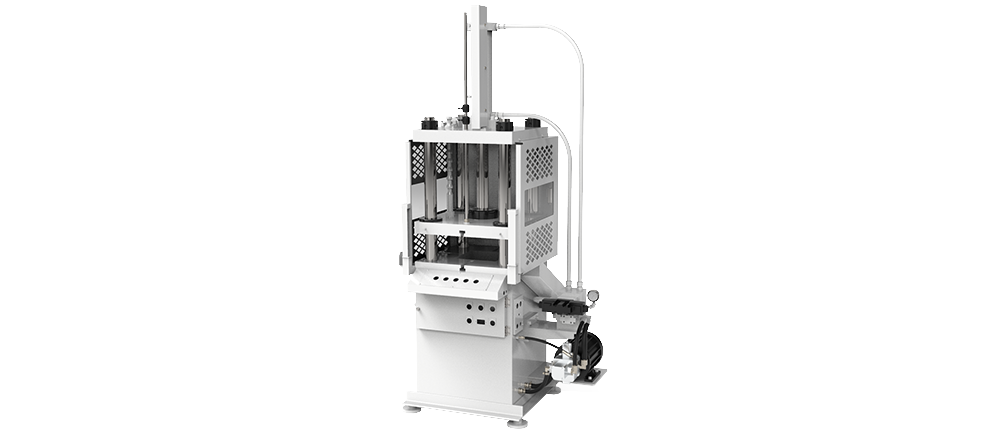

Trim press machine: processing trimming on your semi-finished product in one press. Achieve consistently high-quality performance and improve your working efficiency.

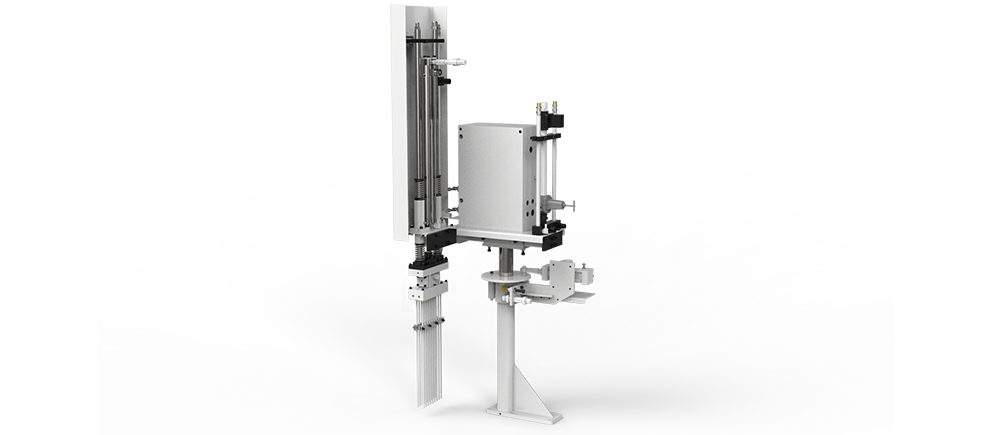

Conveyer: connect your die casting machine to the next station, thus saving time on transportation.

Sprayer: allowing mold-release agent to be sprayed evenly, thus ensuring that your product remains perfect at the time of demolding.

Trim press machine: processing trimming on your semi-finished product in one press. Achieve consistently high-quality performance and improve your working efficiency.

Conveyer: connect your die casting machine to the next station, thus saving time on transportation.

Easy operation

Operation should be easy and instinctive

We make machine easy to operate, so that you only focus on what you need to focus.

Injection digital system: data access at the tip of your fingers. IDS integrates all important injection data on a one touch screen.

Automatic die height adjusting system: Optimal mold height and maximum locking force can be achieved automatically within 1 min.

Parameter memory: Capable of memorizing 50 sets of production parameters. Allows you to correctly and efficiently select parameters and improve your production efficiency.

Trouble shooting: Error and solution information display, providing quick instructions allowing the front-line operator to conduct quick and efficient maintenance.

Auto-lubrication system, extending the service-life of locking system.

Automatic die height adjusting system: Optimal mold height and maximum locking force can be achieved automatically within 1 min.

Parameter memory: Capable of memorizing 50 sets of production parameters. Allows you to correctly and efficiently select parameters and improve your production efficiency.

Trouble shooting: Error and solution information display, providing quick instructions allowing the front-line operator to conduct quick and efficient maintenance.

Auto-lubrication system, extending the service-life of locking system.

More features

Self-equipped inspection: inspecting with coordinate measuring machine and our high standard to ensure all parts are precisely meet the designs. Precise machining: All critical components are processed with precise machining.

High standard material selection: Selecting well-known brands, such as MITSUBISHI, OMRON, YUKEN, HYDAC and more, for our electrical and hydraulic control system.

Stable injection: unique design of gooseneck runner to stable the flow and avoid unexpected bubbles. Through monitoring locking force and injection curve, we ensure the stability for injection.